Self-Organisation and Material Constructions

Cellular biological materials have intricate interior structures, self-organised in hierarchies to produce modularity, redundancy and differentiation.

As Michael Weinstock explains, the foam geometries of cellular materials offer open and ductile structural systems that are strong and permeable, making them an attractive paradigm for developments in material science and for new structural systems in architecture and engineering.

The self-organisation of biological material systems is a process that occurs over time, a dynamic that produces the capacity for changes to the order and structure of a system, and for those changes to modify the behaviour of that system. The characteristics of self-organisation include a 3-D spatial structure, redundancy and differentiation, hierarchy and modularity. Studies of biological systemic development suggest that the critical factor is the spontaneous emergence of several distinct organisational scales and the interrelations between lower or local levels of organisation, the molecular and cellular level, and higher or global levels of the structure or organism as a whole. The evolution and development of biological self-organisation of systems proceeds from small, simple components that are assembled together to form larger structures that have emergent properties and behaviour, which, in turn, self-assemble into more complex structures.3 The geometry of soap foams is a model for the cellular arrangements at all scales in natural physical systems.

Natural Constructions

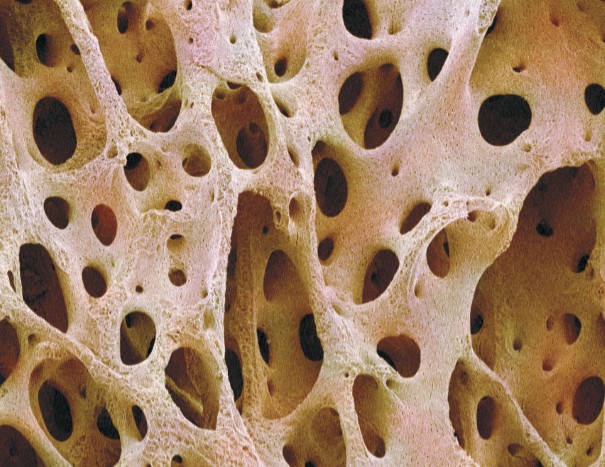

Natural materials develop under load, and the intricate interior structure of biological materials is an evolutionary response. At the level of the individual, there is also an adaptive response as, for example, bone tissue gets denser in response to repeated loads in athletic activities such as weightlifting. Bone is a cellular solid,4 a porous material that has the appearance of mineralised foam, and its interior is a network of very small and intricately connected structures.

Spongy bone tissue

Scanning electron micrograph of cancellous (spongy) bone tissue. Bone can be either cortical (compact solid) or cancellous, with cortical usually forming the exterior of the bone and cancellous tissue forming the interior. The Cellular biological materials have intricate interior structures, self-organised in hierarchies to produce modularity, redundancy and differentiation. As Michael Weinstock explains, the foam geometries of cellular materials offer open and ductile structural systems that are strong and permeable, making them an attractive paradigm for developments in material science and for new structural systems in architecture and engineering. cellular structure is highly differentiated, formed by an irregular network of trabeculae, or rod-shaped fibrous tissue. The open spaces within the tissue are filled with bone marrow.

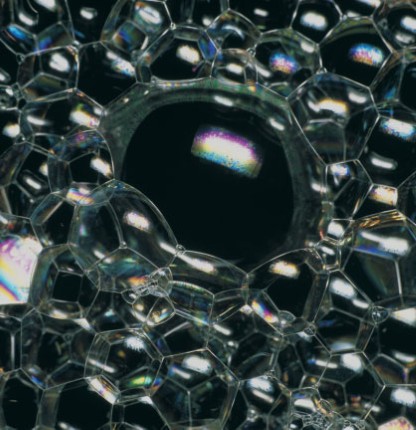

Soap bubbles

A naturally produced foam of soap bubbles, demonstrating the differentiation of polyhedral cells in an intricate geometry of foam architecture, including the basic Plateau rules for the intersection of three films.

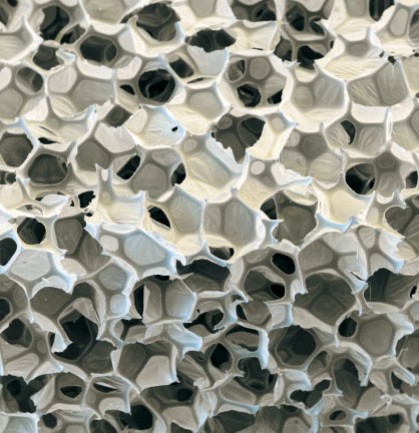

Polyurethane foam wound dressing

Scanning electron micrograph of polyurethane foam, showing the porous structure of differentiated open and partially closed cells. Magnification x 20 when printed at 10 centimetres wide.

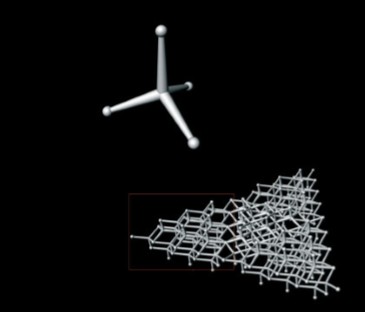

Sponge spicule

Scanning electron micrograph of the endoskeletal component of a sponge made of calcium carbonate. When assembled, the skeleton forms either a mesh or honeycomb structure. Magnification x 210 when printed at 10 centimetres wide.

The process, known as ‘free living radical polymerisation’, can produce honeycomb structures at a molecular level, although the controlled formation of the honeycomb morphology at larger scales is still in the research, rather than production, phase.

APPLICATION OF CONCEPT IN ARCHITECTURAL DESIGNING

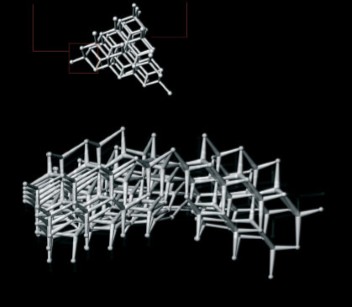

Thomas Von Girsewald and Juan Subercaseaux, centroidal Voronoi tessellation and boundary optimisation in close-packing systems, Emergent Technologies and Design programme, AA Graduate School of Architecture, 2005 Geometric logics were identified from a physical soap-film model and, based on the geometric fundamentals of Plateau’s laws extended into three dimensions (three relaxed soap bubbles can only meet at an angle of exactly 109° 28’ 16”), a four-segment tetrahedral dihedral angle component was digitally designed.

The component was nested inside a layered triangular organisation generating a parametrically deformable triangular tile with regular pentagonal dodecahedra (12-sided) interior cellular partitions. This tile was aperiodically distributed into a larger equilateral configuration with a total population of 152 nested component features. The parametric system permits the manipulation of one single input point to produce an automatic reconfiguration of 114 primary components, maintaining the coherence of the cellular partitions while relocating the respected individual centroid.

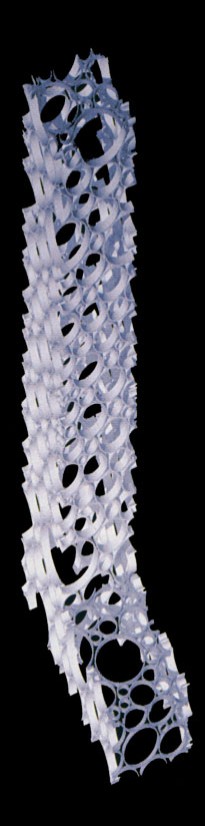

Architektur and Arup, Bubble Highrise, Berlin, 2002

Experimental design from which the design approach to the Watercube was evolved. The structure is produced by running a packing algorithm to fill a notional high-rise volume with differentiated spheres, which are then cut at the surface intersection.

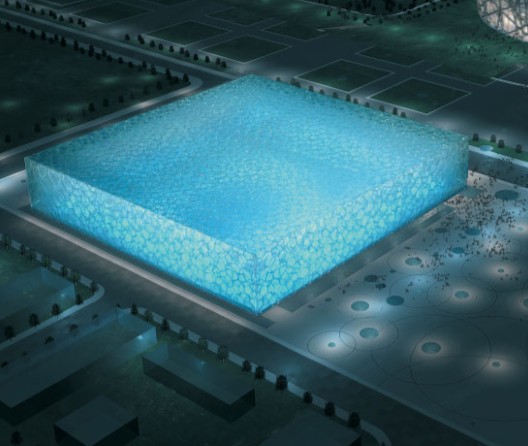

PTW Architects, CSCEG Design and Arup,

‘Watercube’ National Swimming Centre, Beijing, due for completion 2007 Competition model showing overall scale: 177 x 177 metres (581 x 581 feet) and more than 30 metres (98 feet) high, with an entirely column-free interior space.

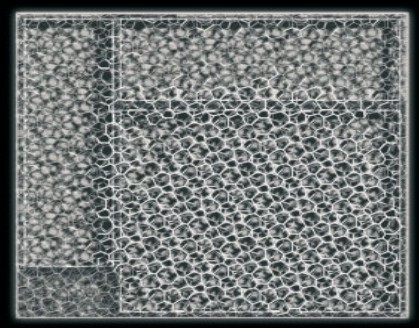

Watercube digital structural model. The mathematics of foam geometries are used to produce the structural array, ensuring a rational optimised and buildable structural geometry.

There is a total of 4000 ‘bubbles’ in the Watercube, the roof being made of only 7 variant types (of bubbles) and the walls of only 16 variations, which are repeated throughout. The geometry was developed by extensive scripting, using the Weaire and Phelan mathematics, with a further script required for a final analytical and geometrical correct 3-D model. Scripts that run in minutes can deal with the tens of thousands of nodes and beam elements, and scripting was also used to develop structural analysis models and models from which drawings were automatically generated.

Watercube physical prototype; cells and ETFE cushions fabricated for the testing of environmental and structural behaviour, and confirmation of production logics.

Bibliography:

1) Techniques and Technologies in Morphogenetic Design : Architectural Design

2) Internet